Introduction

As for ocean transportation particularly on sea, adequate fastening and lashing of the containers is paramount importance so that the passengers, freight and vessels. International standards and regulations toward the choice of material and design for the cargo securing systems should be observed as a way of reducing the perils related to container lashing in sea transport. Therefore, this article focuses with details on the major codes and specifications that govern proper fixing of containers on the ships.

Why Compliance is Vital In a Cargo Securing System

In the case of maritime transport, it is mandatory to put in place cargo securing systems so that containers are not able to move during transporting by sea which may cause accidents with high intensity or loss of goods/ pollutants. Such systems must be effective and also meet the safety requirements prescribed by international standards to protect lives at sea or property in every day operations.

Basic international standards for securing cargo

Many International Organizations set up regulations and codes for their best practice which provides guidance, recommendations on various aspects of safe ty stowage cargo onboard ships. These are the most important:

1. International Maritime Organization (IMO)

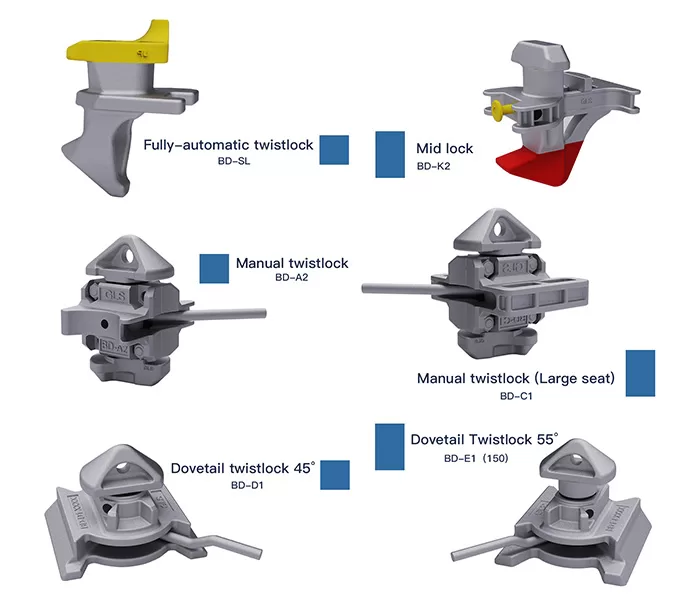

IMO Guidelines on Cargo Securing — The International Maritime Organization (IMO) offers extensive advice for proper cargo securing to guarantee the safe transport of all cargoes, such as containers, across seas. These standards include the specifications for designing, selecting and employing cargo securing devices including twist locks, lashing rods or turnbuckles.

Safety of Life at Sea (SOLAS): Chapter VI in the SOLAS convention prescribes mandatory securing requirements that highlight the necessity for adequate securing arrangements of containers. It requires, amongst others things, maintaining cargo securing equipment in the proper state and training personnel to use it.

2. ISO(pDXIS)

ISO 3874 – Series 1 Freight Containers — Handling and Securing: This International Standardspecifies the requirements for handling and securing of freight containers. This pertains to the utilization of Twist Locks, Base twist locks and some other kind protecting instruments that are necessary as a bit of Container Lashing inside ships.

ISO 1161 " Series 1 freight containers - Corner fittings -- Specification": the specification defined by this standard ensures interchangeability between critical parts of marine transport handling equipment and cargo container corner fittings

3. Classification Societies

Classification Society Role: Classification societies like DNV GL, Lloyd's Register and Bureau Veritas have their rules & guides for cargo securing systems requirements. These instructions sometimes fill in the gaps left by IMO norms and proffer additional precaution for some unique features of various loads or kinds of ships.

Verification and Certification – These societies are also leading the way to ensure that cargo securing systems meet international standards but more importantly they conform to requirements prescribed by various vessels.

Regulations for Lashing Containers

One of the several important factors in maritime shipping is compliance with container lashing regulations. The regulatory needs can be summarized with the following issues;

1. The Right Equipment for Securing

Material & design Various tools such as twist-locks, lashing rods and turnbuckles need to be secured from hardy materials that can withstand the harsh marine environment. To be compatible or reliable, these components must meet ISO standards.

Maximum Load: Each piece of securing equipment has a maximum load that it must not be exceeded. Choosing the right hardware is essential and must be based on the weight and style of container its securing so they do not fail while transporting.

2. Inspection And Maintenance on a Regular Basis

Pre- Voyage Inspection: All cargo securing systems must be inspected and certified to work correctly before a ship sets sail. That can involve visual inspections for rust smearing, wear points and other flaws that degrade component integrity.

Regular checks: Along the journey, consistent inspections need to be done. All the damaged components should be repaired at the earliest to keep your load safe.

3. Physical Qualification of Personnel

Learn how to get your crews certified on the proper handling and securing of container loading. These programs need to explain how to correctly use securing equipment, or lashings; load limits and hazards.

Certification – in many places, there are certification requriements for cargo securing personnel This means that only those who are eligible to work do these jobs, which minimizes the chance of making mistakes.

Best practices for compliance

In order to assure they are compliant with international standards and regulations, it is necessary for companies be able to implement best practices in cargo securing.

1. Implementing a Securing Plan

Formulate a Comprehensive Securing Plan: Every journey must have their securing plan, indicating how containers are to be secured and with which tools concomitantly assigning the responsibility for each case. The plan shall be based on the relevant factors of cargo and expected sea conditions.

Prey on ChecklistsBelieve it or not, squirreling away the same item you just stole in your pocket after looking around frantically isn't something dumb criminals do purposely; but as someone who wants to turn smart crosses that refuse stealing passengers & cargo without much trouble into actual allies during committing crimes and at night heists alike: use checklists.A checklist ensures all essential securing actions are taken before setting sail. This means checking that all equipment is on site, correctly fitted and maintained.

2. Keeping Security Tools Up-to-Date

International standards and cargo securing regulations are continuously updated. Make sure to follow them closely Keep abreast of this and adjust as necessary the securing equipment.

New Replacing the Old: The best securing equipment will still wear out over time. Change-out On A Regular Basis – Having old or broken equipment is a recipe for failure and often dangerous.

3. Track and document continuously

In-Transit Monitoring: In-transit checking on cargo securing systems identifies problems well in advance so that timely corrections can be made and avert accidents.

Record Keeping: Keep thorough records of all inspections, maintenance and recovery activities. It could be useful for references requirements during audits or investigations.

Conclusion

Managing cargo securing— and more broadly speaking, maritime shipping — in accordance with international standards and regulations is crucial. Through adherence to standards set by organizations such as the IMO, ISO and class societies, shipping companies can address container lashing risks in enhanced operational safety. Best practice standards, ongoing training and monitoring will further strengthen compliance and reliability of cargo securing.