Essential Elements of a Container Lashing Plan

In the realm of maritime transport, container lashing is a critical aspect. It ensures the safe and secure transit of cargo across the globe.

A container lashing plan is a detailed blueprint. It outlines how to secure containers on a ship to prevent movement during transit.

The importance of a well-executed container lashing plan cannot be overstated. It not only safeguards the cargo but also the crew, the vessel, and the environment.

This article delves into the essential elements of a container lashing plan. It covers key components like the lashing bar, stacking cone, bridge fitting, and twist lock.

We will also explore the principles of load distribution and the significance of securing points. The types of lashing equipment and their specific applications will be discussed.

Understanding the dynamics of cargo movement and calculating lashing strength are also crucial. We will touch upon these aspects as well.

By the end of this guide, you will have a comprehensive understanding of container lashing plans. This knowledge will be invaluable for professionals in the shipping and logistics industry, as well as anyone interested in maritime safety.

Understanding Container Lashing and Its Importance

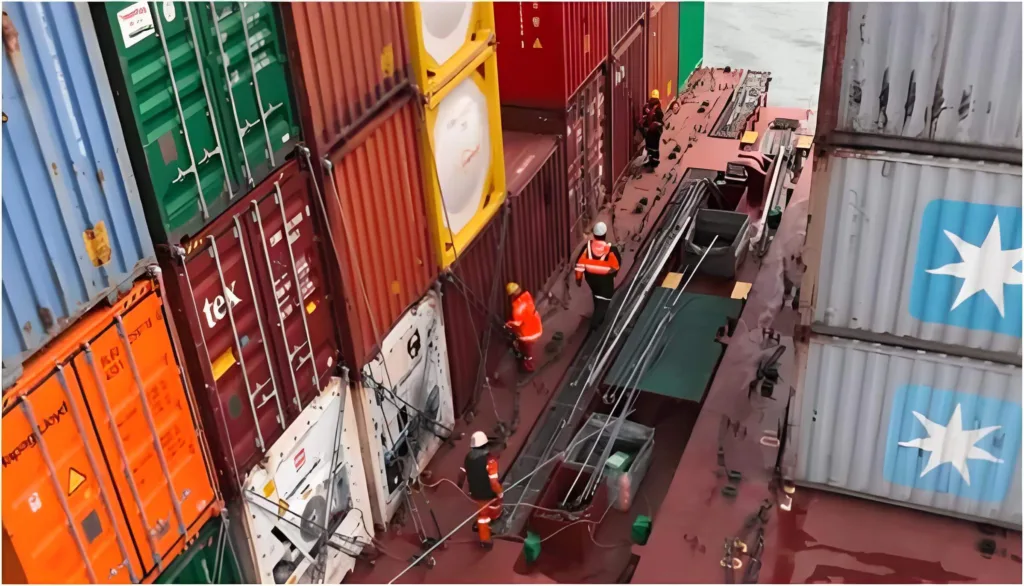

Container lashing is a process that involves securing containers on a ship. It is done using various types of equipment and techniques. The primary goal is to prevent the containers from moving or falling overboard during transit.

The importance of container lashing lies in its role in ensuring maritime safety. Unsecured or poorly secured containers can shift or topple during transit. This can lead to dangerous situations, including cargo damage, injuries to crew members, and even capsizing of the ship.

Container lashing also plays a significant role in maintaining the stability of the ship. Properly secured containers help distribute the weight evenly across the ship. This balance is crucial in preventing the ship from listing or rolling excessively in rough seas.

The key elements that contribute to effective container lashing include:

- Understanding the dynamics of cargo movement

- Proper use of lashing equipment

- Adherence to safety regulations and standards

- Regular inspection and maintenance of lashing equipment

- Training and competency of personnel involved in lashing operations

In the following sections, we will delve deeper into these elements. We will explore the various components of a container lashing system, the principles of load distribution, and the importance of securing points. We will also discuss the types of lashing equipment, how to calculate lashing strength, and the regulations and standards that govern container lashing.

Key Components of a Container Lashing System

A container lashing system comprises several components. Each plays a unique role in securing the containers on a ship. The main components include lashing bars, stacking cones, bridge fittings, and twist locks.

Lashing bars are used to secure containers to each other and to the ship. Stacking cones help maintain the alignment of stacked containers. Bridge fittings contribute to the stability of container stacks. Twist locks secure containers to each other and to the ship.

Understanding the function of each component is crucial. It helps in the effective use of the lashing system. It also aids in the maintenance and inspection of the lashing equipment.

The key components of a container lashing system include:

In the following subsections, we will explore each of these components in detail.

Lashing Bars

Lashing bars are long metal rods. They are used to secure containers to each other and to the ship. One end of the lashing bar is hooked into a securing point on the container or the ship. The other end is tightened using a turnbuckle.

The use of lashing bars helps prevent lateral and vertical movement of containers. This is crucial in maintaining the stability of the cargo during transit.

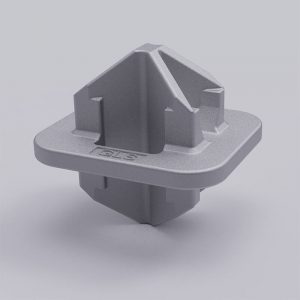

Stacking Cones

Stacking cones are cone-shaped devices. They are placed in the corner castings of containers. They help maintain the alignment of stacked containers.

Stacking cones contribute to the stability of container stacks. They also facilitate quick and easy stacking and unstacking of containers.

Bridge Fittings

Bridge fittings are used to connect containers horizontally. They are placed in the corner castings of adjacent containers. They help maintain the stability of container stacks.

Bridge fittings are crucial in preventing lateral movement of containers. They also contribute to the overall stability of the ship.

Twist Locks

Twist locks are devices used to secure containers to each other and to the ship. They are inserted into the corner castings of containers. A twist of the handle locks or unlocks the device.

Twist locks are crucial in preventing vertical movement of containers. They also contribute to the overall stability of the cargo and the ship.

The Role of Load Distribution in Container Stowage

Load distribution plays a crucial role in container stowage. It refers to the arrangement of containers on a ship in a way that balances the weight. Proper load distribution is essential for the stability of the ship and the safety of the cargo.

The principles of load distribution include:

- Placing heavier containers at the bottom and lighter ones at the top.

- Distributing the weight evenly from bow to stern and from port to starboard.

- Avoiding high stacks of containers on the ends of the ship to prevent tipping.

These principles help maintain the ship's balance. They also minimize the risk of containers tipping over or sliding during transit.

Improper load distribution can lead to serious problems. It can cause the ship to list or capsize. It can also lead to damage or loss of cargo.

Understanding and applying the principles of load distribution is a key aspect of a container lashing plan. It ensures the safety and efficiency of maritime transport.

Identifying and Utilizing Securing Points

Securing points are specific locations on a container where lashing equipment can be attached. They are integral to the container lashing plan. Identifying and utilizing these points correctly is crucial for the stability and safety of the cargo.

Each container has several securing points. These are typically located at the corners and along the sides of the container. The type and size of the container, as well as the cargo inside, can influence the number and location of these points.

Using the right securing points helps distribute the load evenly. It also ensures that the lashing equipment can effectively secure the container. Understanding the role and location of securing points is a key element of a successful container lashing plan.

Types and Applications of Lashing Equipment

Lashing equipment is the backbone of any container lashing plan. It is designed to secure containers during transit, preventing movement and potential damage. There are several types of lashing equipment, each with its specific application.

Lashing bars, for instance, are used to secure containers to each other and to the ship. They are typically made of high-strength steel and come in various lengths to accommodate different container sizes. Lashing bars are essential for maintaining the stability of stacked containers.

Stacking cones, on the other hand, are used to align containers and keep them in place. They are inserted into the corner castings of containers, providing a secure connection between stacked containers. Stacking cones play a crucial role in maintaining the alignment and stability of container stacks.

Bridge fittings and twist locks are other key components of a container lashing system. Bridge fittings are used to connect containers horizontally, while twist locks secure containers vertically. Both are critical for ensuring the stability of container stacks during transit.

In summary, the types of lashing equipment used in a container lashing plan include:

- Lashing bars

- Stacking cones

- Bridge fittings

- Twist locks

Each type of equipment has a specific role in securing containers, contributing to the overall safety and efficiency of maritime transport. Understanding the types and applications of lashing equipment is essential for creating an effective container lashing plan.

Calculating Lashing Strength and Understanding Cargo Dynamics

Lashing strength is a critical factor in a container lashing plan. It refers to the maximum force that lashing equipment can withstand without failing. Calculating lashing strength involves considering the weight of the cargo, the forces acting on it during transit, and the strength of the lashing equipment.

Understanding cargo dynamics is also crucial. During transit, containers are subjected to various forces such as rolling, pitching, and heaving. These forces can cause the cargo to shift, potentially leading to instability or damage. Therefore, a container lashing plan must account for these dynamics to ensure the safety and integrity of the cargo.

To calculate lashing strength and understand cargo dynamics, consider the following:

- The weight and distribution of the cargo

- The forces acting on the cargo during transit

- The strength and condition of the lashing equipment

In conclusion, calculating lashing strength and understanding cargo dynamics are essential elements of a container lashing plan. They help ensure that the lashing equipment can withstand the forces acting on the cargo, thereby preventing cargo movement and potential damage.

Adhering to Regulations and Standards

Adherence to regulations and standards is a fundamental aspect of a container lashing plan. These rules are set by international bodies like the International Maritime Organization (IMO). They ensure that lashing practices meet safety and efficiency requirements.

Regulations cover various aspects of container lashing. These include the design and maintenance of lashing equipment, the calculation of lashing strength, and the training of personnel. Standards, on the other hand, provide guidelines on best practices for container lashing. They help ensure consistency and quality in lashing operations across the industry.

In conclusion, adhering to regulations and standards is crucial in container lashing. It ensures safety, efficiency, and consistency in lashing operations. It also helps prevent accidents and cargo damage, thereby enhancing the reliability and reputation of shipping companies.

Designing an Effective Container Lashing Plan

Designing an effective container lashing plan is a complex process. It requires a deep understanding of the cargo, the ship, and the journey. The plan must consider the weight and type of cargo, the ship's design, and the expected weather conditions.

The lashing plan should also consider the ship's route. Different routes may expose the ship to different weather conditions and sea states. These factors can significantly affect the effectiveness of the lashing plan.

A well-designed lashing plan should also be flexible. It should allow for adjustments based on changes in cargo, weather, or other unforeseen circumstances. This flexibility can help ensure the safety and integrity of the cargo throughout the journey.

Best Practices for Implementation

Implementing a container lashing plan requires careful coordination and communication. All personnel involved in the lashing process should understand their roles and responsibilities. They should also be trained in the use of lashing equipment and the execution of the lashing plan.

Regular inspections and maintenance of lashing equipment are also crucial. This ensures that the equipment is in good condition and can perform its function effectively.

Technology's Role in Modern Lashing Systems

Technology plays a significant role in modern container lashing systems. Advanced software tools can help design and validate lashing plans. They can simulate different scenarios and provide insights into the effectiveness of the lashing plan.

Automation is also becoming increasingly prevalent in container lashing. Automated lashing systems can improve efficiency and reduce the risk of human error.

Case Studies and Lessons Learned

Case studies of past lashing failures can provide valuable lessons. They can highlight potential pitfalls and provide insights into how to avoid similar issues in the future. Learning from these experiences is crucial for improving the safety and effectiveness of container lashing plans.

Training, Competency, and Maintenance of Lashing Equipment

Training and competency are critical in the successful implementation of a container lashing plan. All personnel involved in the lashing process should have a thorough understanding of the plan and the equipment used. They should be trained in the correct use of lashing equipment, including lashing bars, stacking cones, bridge fittings, and twist locks.

In addition to training, regular maintenance of lashing equipment is essential. This includes routine inspections to identify any signs of wear and tear or damage. Any faulty equipment should be repaired or replaced promptly to ensure the safety and effectiveness of the lashing system.

Moreover, continuous learning and adaptation are crucial in the ever-evolving field of container lashing. As new technologies and techniques emerge, it's important for personnel to stay updated and adapt their practices accordingly. This ensures that the lashing plan remains effective and up-to-date with industry standards.

Conclusion: The Future of Container Lashing

The future of container lashing is promising, with advancements in technology and automation paving the way for more efficient and safer practices. As the shipping industry continues to evolve, so too will the methods and equipment used in container lashing.

In conclusion, a well-designed and implemented container lashing plan is crucial for maritime safety. By understanding the essential elements of a container lashing plan and adhering to industry standards and regulations, we can ensure the safe and efficient transport of cargo across the world's oceans.