A proper fixing of the container on the ships plays a very important role in the absence of accidents during the shipment of goods through the ships. The post aims at discussing different types of applied materials and devices for fastening of the containers on the ships and their comparative characteristics. Knowledge of these will assist the shipping companies make the right choices so that the consignment of goods will be safe.

Types of Container Lashing Materials for Confinement on Ships

There are several materials as well as devices that are typically used for the purpose of some kind of container fixing on the ships. These include:

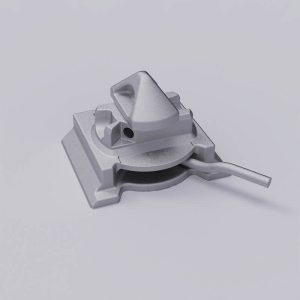

- Twist Locks

- Base Twist Locks

- Bridge Fittings

- Corner Castings

- Lifting Lugs

- Lashing Plates

- Guide Cones

- Turnbuckles

- Lashing Bars

Advantages:

Ease of Use: Twist locks are easy to engage and disengage, facilitating quick securing and releasing of containers.

Standardization: Widely used and standardized, ensuring compatibility across different shipping lines.

Security: Provides a high level of security and stability for stacked containers.

Disadvantages:

Limited Adjustability: Once engaged, they do not allow for tension adjustments.

Maintenance: Requires regular inspections and maintenance to ensure proper functioning.

Initial Setup: Requires precise installation to ensure effectiveness.

Base Twist Locks

Advantages:

Enhanced Stability: Base twist locks provide additional stability to containers, especially the ones placed at the bottom of the stack.

Ease of Use: Similar to regular twist locks, they are easy to use and engage.

Security: Offers robust securing at the base, critical for overall stack integrity.

Disadvantages:

Complexity: Requires another layer on the top of the containers’ protection which, in turn, takes a bit more time to set up.

Maintenance: This is why they require some form of periodic inspection so that they may continue to serve their intended function effectively.

Weight: Supplements the additional weight to the securing system.

Bridge Fittings

Advantages:

Stability: Enhances container stacks in order to have added stability particularly especially during stormy seas.

Compatibility: May also be used in conjunction with other securing techniques such as twist lock and lashing rods.

Flexibility: Suitable for various container sizes and configurations.

Disadvantages:

Complexity: It may require lot of efforts and time to install it.

Weight: Increases the load of the securing system.

Cost: May be costly since it involves the use of extra compounds and work force.

Corner Castings

Advantages:

Durability: Constructed from rugged high strength steel material for best efficiency in the long run.

Standardization: The standardized dimensions are useful in providing compatibility with several securing devices.

Versatility: Grade includes twist locks, bridge fittings as well as other fastening tools.

Disadvantages:

Weight: Contributes to the additional weight of container.

Installation: Demands massive clamping force at the time of welding and also during its assembly.

Maintenance: Conducts by overheating routine checks to learn of any structural deformity.

Lifting Lugs

Advantages:

Ease of Lifting: offers support anchor points for lifting gadgets offering a safe means through which equipment handling can be done.

Strength: Catering for the loading operations where lifting of loads is done in a safe manner.

Versatility: It may be adapted to be used with other lifting tools and equipment such as civil engineering.

Disadvantages:

Installation: Demands a strong quality control especially when it comes to welding and installation of the required safety measure.

Cost: May be costly because the structure needs to be very strong and therefore the incorporation of expensive material.

Maintenance: It requires frequent check-up in a bid to ensure that some of the parts have not worn out.

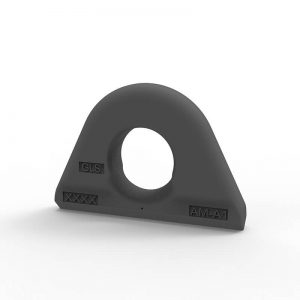

Lashing Plates

Advantages:

Flexibility: Gives many possibilities for securing with lashing devices enhancing the stability.

Strength: It is highly resistant to abrasive and corrosive load that can be exerted on it and in other poor working environments.

Compatibility: It can be applied with some forms of lashing such as rods and turnbuckles.

Disadvantages:

Installation: It calls for right welding as well as proper placing when the containers are produced.

Maintenance: It important they are checked frequently to ensure they are still secure and functional.

Cost: Could bring the cost of manufacturing containers to the overall cost of containing good higher.

Guide Cones

Advantages:

Alignment: Assists in achieving proper orientation of containers during piling in a bid to prevent movement during transportation.

Ease of Use: They are very easy to install as well as to uninstall, owing to their basic structure.

Cost-Effective: Normally cheaper compared to other complicated securing systems that can be incorporated into construction.

Disadvantages:

Limited Security: Offers base stabilizing, and does not work for all sea conditions.

Durability: May be more sensitive and thus wear out faster; this means that they need constant replacement.

Dependence on Other Systems: Sometimes used in conjunction with other securing methods to boost the stability of a company.

Turnbuckles

Advantages:

Adjustability: Enables effective tuning of tension of screws so that the containers are well secured.

Strength: Constructed from very strong materials to be able to bear heavy load.

Durability: Intended for heavily marine conditions.

Disadvantages:

Weight: They can be rather heavy, and this makes pulling and mounting them to prove to be time-consuming processes.

Corrosion: Must be refurnished from time to time because of its exposure to salty water that cause corrosion.

Cost: Higher initial cost than simple means of securing a building or a room.

Lashing Bars

Advantages:

Strength: Affords good and powerful securing for containers.

Flexibility: It can be applied in numerous forms so as to ensure all sorts of commodities.

Durability: Constructed from strong material to enable them undergo the process of sea transport.

Disadvantages:

Weight: Relative to the other security approaches, this one increases the sum weight of the object.

Handling: This process has to be done manually and therefore may be time consuming.

Maintenance: Tends to become ineffective hence requires regular inspection.

Selection Criteria for the Appropriate Material Used in Securing Containors on Ships

The proper choice of the securing material is also defined by the characteristics of the containers to be secured, their weight, the sailing area, and expected conditions on the sea. Here are some considerations:

Cargo Type: For additional or bigger and heavy containers, lashing rods and turnbuckles may also be used while for lighter ones, twist locks may suffice.

Cost: It is quite possible that because of the lack of funds, the right or preferred material may be chosen.

Environmental Factors: Think about the marine environment in which the containers are to be transported to consider. The use of material that cannot easily be degraded by moisture, or saline environment is recommended.

Ease of Use: Products such as twist locks that can be easily fitted very fast to a ship can be effective in increasing the operations efficiency.

Regarding the matters of container securing on ships, definite best practices can be determined.

Implementing best practices ensures the effectiveness of securing systems:Implementing best practices ensures the effectiveness of securing systems:

Assessment: Categorise the containers based on the type of the load they are carrying and their weight so as to be able to define the best method for securing the load.

Equipment: Utilize securing media and equipment that are suitable for marine use.

Training: Train all the employees that are involved in securing containers, regarding the processes to follow and safety measures to take.

Inspection: Check the securing materials and containers being used during transportation often to guarantee that the items are still well secured.

Compliance: Accomplish all the legal requirements governing the maritime industry to safeguard the vessels and all the users in the process.

Conclusion

The basics of various materials used for securing of containers on ships relate to the trade off between the kind of material that offers a lot of opportunity for securing the containers as well as some of the challenges that may be involved when they are used for the same task. When choosing the proper material for every shipping company’s application and incorporating the best practices for each maritime logistics organization, shipping companies can decrease the chances of accidents and improve overall safety.