In the maritime industry, lashing plans are crucial. They ensure the safety and efficiency of container ship operations.

But what exactly are lashing plans?

Simply put, they are strategic plans for securing cargo on a ship. They prevent cargo from shifting or falling overboard during transit.

Creating an effective lashing plan is not a simple task. It requires a deep understanding of various factors. These include the type of cargo, the ship's stability, and the expected weather conditions.

In this comprehensive guide, we delve into the best practices for creating effective lashing plans. We will explore the planning process, the selection of lashing tools, and the implementation of container ship lashing services.

This guide is designed for maritime professionals. Whether you are a ship operator, a cargo handler, a logistics manager, or a safety officer, you will find valuable insights here.

Understanding the Importance of Lashing Plans

Lashing plans are more than just a procedural requirement. They are a critical component of maritime safety and cargo security.

Without a well-executed lashing plan, cargo can shift during transit. This can lead to dangerous situations. It can cause the ship to list or even capsize, endangering the crew and the environment.

Moreover, improperly secured cargo can lead to significant financial losses. Damaged goods, delays in delivery, and potential legal liabilities can all result from poor lashing.

Understanding the importance of lashing plans is the first step towards creating effective ones. Here are some key reasons why lashing plans are essential:

- Safety: Proper lashing ensures the safety of the crew and the ship. It prevents cargo from shifting, which can cause instability and accidents.

- Cargo Security: Lashing plans protect the cargo from damage during transit. They ensure that the goods reach their destination in the same condition they were loaded.

- Regulatory Compliance: Maritime regulations require ships to have a lashing plan. Compliance with these regulations is crucial to avoid penalties and maintain a good reputation in the industry.

- Efficiency: Effective lashing plans contribute to the overall efficiency of shipping operations. They allow for optimal use of space and reduce the time required for loading and unloading.

In the following sections, we will delve deeper into the best practices for creating effective lashing plans. We will cover everything from regulatory standards to the selection of lashing tools. Let's start by understanding the regulatory landscape for container lashing.

Regulatory Standards and Guidelines for Container Lashing

The maritime industry operates under a comprehensive set of regulations. These rules ensure the safety and efficiency of shipping operations. Among these regulations, several pertain specifically to container lashing.

The International Maritime Organization (IMO) is the primary regulatory body for maritime safety. It has established guidelines for securing cargo, including containers. These guidelines are outlined in the Cargo Securing Manual (CSM) that every ship must carry.

The CSM provides detailed instructions for lashing and securing different types of cargo. It includes information on the correct use of lashing equipment and the maximum allowable stack weights. The manual also provides guidance on how to adjust lashing in response to weather conditions and sea states.

In addition to the IMO, classification societies also play a crucial role in regulating container lashing. These independent organizations establish technical standards for the design, construction, and maintenance of ships. They also certify lashing arrangements and equipment to ensure they meet these standards.

Compliance with these regulatory standards is not just a legal requirement. It is a fundamental aspect of creating effective lashing plans. By adhering to these guidelines, shipping companies can ensure the safety of their operations and protect their cargo from damage. In the next section, we will provide a step-by-step guide to developing a container lashing plan.

Step-by-Step Guide to Developing a Container Lashing Plan

Developing an effective lashing plan is a meticulous process. It requires a deep understanding of the ship's characteristics, the nature of the cargo, and the expected weather conditions. Here is a step-by-step guide to creating a robust container lashing plan.

The first step is to understand the ship's stability and stack weight distribution. This involves studying the ship's design and load-bearing capacity. It also requires knowledge of the ship's center of gravity and the impact of cargo weight on the ship's stability.

Next, you need to consider the type of cargo being transported. Different types of cargo require different lashing techniques and equipment. For instance, heavy cargo may require stronger lashing gear and more securement points.

The third step is to consider the expected weather conditions during the voyage. High winds and rough seas can exert significant forces on the cargo. Therefore, the lashing plan must be designed to withstand these forces.

Once these factors are considered, you can start developing the lashing plan. This involves deciding on the placement of containers, the type of lashing gear to be used, and the lashing pattern. The aim is to distribute the weight evenly and secure the cargo effectively.

The lashing plan should also include contingency measures for unexpected situations. This could involve additional lashing gear for use in severe weather or procedures for adjusting lashing during the voyage.

Finally, the lashing plan must be documented and communicated to all relevant personnel. This includes the ship's crew, cargo handlers, and shore-based staff. Clear communication ensures that everyone understands their roles and responsibilities in implementing the lashing plan.

In conclusion, developing a lashing plan is a complex task that requires careful planning and coordination. However, by following these steps, you can create a lashing plan that ensures the safe and secure transportation of your cargo.

In conclusion, developing a lashing plan is a complex task that requires careful planning and coordination. However, by following these steps, you can create a lashing plan that ensures the safe and secure transportation of your cargo.

Selecting the Right Lashing Tools for Container Shipping

Selecting the right lashing tools is a critical aspect of developing an effective lashing plan. The choice of tools can significantly impact the safety and security of the cargo. Therefore, it's essential to understand the different types of lashing tools available and the criteria for selecting the right tools based on the cargo type.

There are several factors to consider when selecting lashing tools. These include the type and weight of the cargo, the expected weather conditions, and the ship's design. It's also important to consider the durability and reliability of the lashing tools, as they must withstand the forces exerted during the voyage.

Types of Lashing Tools and Equipment

There are various types of lashing tools and equipment used in container shipping. These include lashing bars, turnbuckles, and twistlocks. Lashing bars are used to secure containers to each other and to the ship. Turnbuckles are used to tighten the lashing bars, ensuring a secure fit. Twistlocks are used to lock containers in place, preventing them from moving during the voyage.

In addition to these, there are also lashing chains and wire ropes. These are used for heavy cargo and in situations where additional securing is required. Lashing chains are strong and durable, making them ideal for heavy loads. Wire ropes, on the other hand, are flexible and can be used in a variety of lashing configurations.

Criteria for Tool Selection Based on Cargo Type

The selection of lashing tools is largely dependent on the type of cargo being transported. For instance, heavy cargo requires stronger lashing tools, such as lashing chains and wire ropes. On the other hand, lighter cargo can be secured with lashing bars and turnbuckles.

It's also important to consider the shape and size of the cargo. Irregularly shaped cargo may require special lashing tools or custom-made securing devices. Similarly, oversized cargo may require additional securing points and stronger lashing gear.

In conclusion, the selection of lashing tools is a critical aspect of lashing plan development. By understanding the different types of tools available and the criteria for their selection, you can ensure the safe and secure transportation of your cargo.

Implementing container ship lashing services involves a series of steps. These steps are designed to ensure the safety and security of the cargo during the voyage. The process begins with the development of a lashing plan, which outlines the lashing strategy for the cargo.

The lashing plan is based on several factors. These include the type and weight of the cargo, the ship's design, and the expected weather conditions. The plan also takes into account the lashing tools and equipment that will be used.

Once the lashing plan is developed, the next step is to implement the plan. This involves securing the cargo using the selected lashing tools and equipment. The cargo is secured in a way that minimizes movement during the voyage.

The implementation of the lashing plan is not a one-time process. It requires continuous monitoring and adjustment throughout the voyage. This ensures that the cargo remains secure, even in changing weather conditions or in the event of unexpected incidents.

The Role of Weather Conditions in Lashing Strategies

Weather conditions play a significant role in lashing strategies. High winds, rough seas, and extreme temperatures can all impact the effectiveness of the lashing plan. Therefore, it's important to consider the expected weather conditions when developing the lashing plan.

For instance, in rough seas, the cargo may be subjected to greater forces. This may require additional securing points or stronger lashing gear. Similarly, in high winds, the cargo may be at risk of being blown off the ship. This may require the use of wind-resistant lashing tools and techniques.

In conclusion, weather conditions can significantly impact the effectiveness of the lashing plan. By considering the expected weather conditions, you can develop a lashing strategy that ensures the safety and security of the cargo, regardless of the weather.

Techniques for Securing Containers on Different Vessels

Different types of vessels require different lashing techniques. For instance, container ships require a different lashing strategy compared to bulk carriers or tankers. This is due to the differences in the design and operation of these vessels.

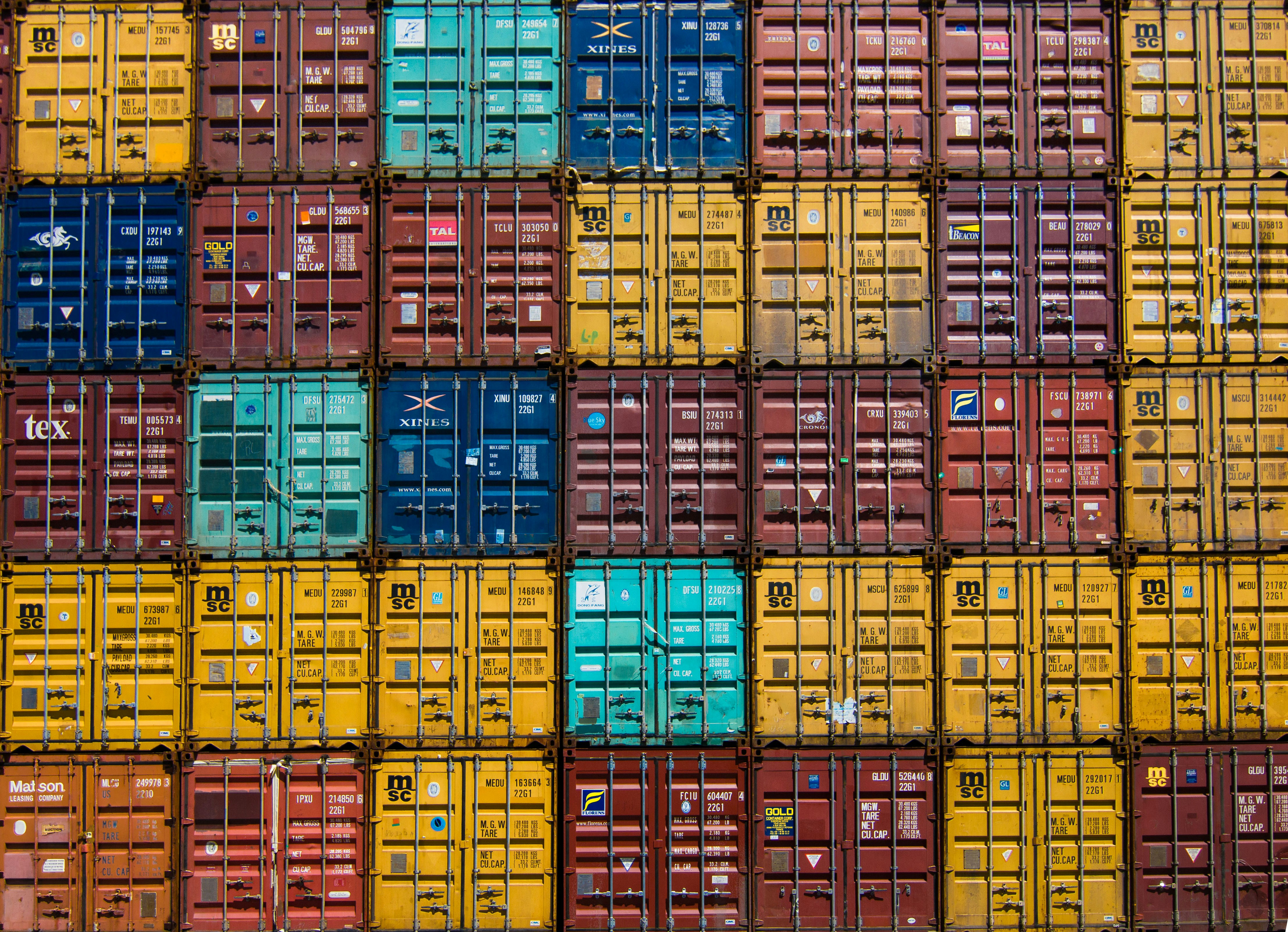

On container ships, the containers are stacked on top of each other. This requires the use of lashing bars, turnbuckles, and twistlocks to secure the containers to each other and to the ship. The lashing strategy also needs to take into account the stack weight distribution to ensure the stability of the ship.

On bulk carriers and tankers, the cargo is often loose or in liquid form. This requires a different lashing strategy. The cargo needs to be evenly distributed to maintain the stability of the ship. In addition, the cargo needs to be secured to prevent shifting during the voyage.

In conclusion, the type of vessel plays a significant role in the lashing strategy. By understanding the different lashing techniques required for different vessels, you can ensure the safe and secure transportation of your cargo.

Monitoring and Adjusting Lashing During Voyages

Monitoring and adjusting lashing during voyages is a critical aspect of container ship operations. It ensures the ongoing safety and security of the cargo. This process involves regular checks of the lashing equipment and the condition of the cargo.

During these checks, the crew assesses whether the lashing is still secure. They look for signs of loosening or damage to the lashing equipment. If any issues are identified, the lashing is adjusted or repaired as necessary. This might involve tightening lashing bars, replacing damaged turnbuckles, or repositioning containers.

In conclusion, continuous monitoring and adjustment of lashing during voyages is a best practice in container shipping. It helps to prevent cargo damage and loss, and contributes to the overall safety of the ship and its crew.

Leveraging Technology: Lashing Software and Automation

In the modern shipping industry, technology plays a crucial role in enhancing the efficiency and safety of operations. This is particularly true when it comes to lashing plans. Lashing software and automation tools are increasingly being used to streamline the planning process and ensure optimal results.

Lashing software allows for the simulation of different lashing scenarios. It takes into account various factors such as the type of cargo, the ship's stability, and weather conditions. This helps in creating a more accurate and effective lashing plan.

Automation, on the other hand, can help in the actual implementation of the lashing plan. Automated lashing systems can perform tasks such as tightening and loosening lashings, reducing the risk of human error.

In conclusion, leveraging technology in the form of lashing software and automation can significantly improve the effectiveness of lashing plans. It not only enhances safety but also increases operational efficiency.

Conclusion: The Future of Lashing Plans and Continuous Improvement

As the shipping industry continues to evolve, so too will the practices for creating effective lashing plans. The advent of larger container ships, the increasing use of automation, and the growing emphasis on environmental sustainability are all factors that will shape the future of lashing plans.

Continuous improvement is key in this regard. By constantly reviewing and updating lashing plans, shipping companies can ensure that they are always adhering to the best practices. This not only enhances the safety and efficiency of operations but also helps in meeting regulatory requirements and industry standards.

In conclusion, the creation of effective lashing plans is a complex but crucial aspect of container shipping. By following the best practices and leveraging the right tools and technologies, shipping companies can ensure the safe and secure transportation of containers by sea.